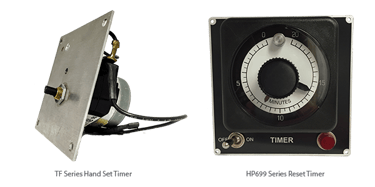

Do you have timing control applications and cannot find the right solution? Don’t reinvent the timer. Eagle Signal has what you are looking for in the TF Hand Set Timer series and the HP699 Reset Timer series. These electromechanical timers are easy to set up. They will run smooth and accurate out of the box.

5 Reasons to Choose Eagle Signal for your Time Control Solution

- Easy to use

No codes, no programming, no problem! The TF Series and the HP699 Series both operate by turning the knob shaft clockwise to set time and rotates counterclockwise during timing for cycle progress indication. Setting these timers are a breeze. The HP699 Series is capable of 0-20 minute timing, while the TF Series can accommodate 0-15 minute or 0-60 minute timing depending on the model.

- Easy to Install, Connect and Design In

Both timer series have 115and 230 VAC 60 Hz models available. The TF Series are suitable for 50 or 60 Hz operation.

- Rugged and Reliable

The TF Series and HP699 Series are virtually immune to voltage variations and transient spikes, therefore offering a long life dependable solution even in this age of high tech electronic devices. The TF Series is built with heavy duty snap action contacts and a heavy duty buzzer which operates until attended to by turning the knob shaft to the "off" position. The HP699 Series has a vast design with a toggle switch for start/stop/reset. The HP699 Series is also highly resistant to cleaning/degreasing agents.

- Customizable

Being customizable is great when is comes to your business and your brand. The TF Series allows for an OEM to integrate their own brand through custom knobs and dial graphics. The TF Series does all the timing behind the scenes. The HP699 Series allows for custom knobs to incorporate the OEM brand.

- Manufactured in the U.S.A.

Both timer series are manufactured in the Elizabethtown, North Carolina.

Timers using electromechanical technology are generally driven by internal electric synchronous motors. A synchronous motor is highly accurate as its speed is controlled by the frequency of the AC power line during its operation. Since the frequency of the power line is constant, the resulting timing is likewise highly accurate, and voltage variations will not affect the motor’s speed. The motor in an electrical timer is engaged to the remaining timing elements by way of a mechanical positive toothed clutch or friction clutch that may be operated by a coil or may be designed to operate as continuously engaged. When line power is applied to the timer, the motor (and clutch) transmit the rotary motion to the other timing components, and when the set point or timeout position is reached the mechanisms involved will operate an output switch. The output switch is connected to the load which is being controlled by the timer and the output contacts change their state upon timeout.

Electromechanical timers may be configured to operate in various timing modes, such as on-delay, off-delay, and interval sequences. From the standpoint of a machine operator, short order cook, process technician, or numerous other users in widely varying applications, the electrical timer stands out in the crowd where ease of use is an important consideration. No codes, no programming, no problem!

Learn more about these timer series by downloading their catalog sheets.